We have fully trained technicians and engineers available to offer advice and assistance on all aspects renewables.

As part of our service of design, supply, installation and commissioning of your renewable systems we will undertake the following dependent on our quotation * :

Design

- Full Site Survey – to assess all aspects of planning compliance, site layout, and future system suitability

- Heat Loss Calculations – to assess all aspects of planning compliance, site layout, and future system suitability

- Sizing – identify correct product based on heat loss and hot water demand and location siting parameters and emitter design

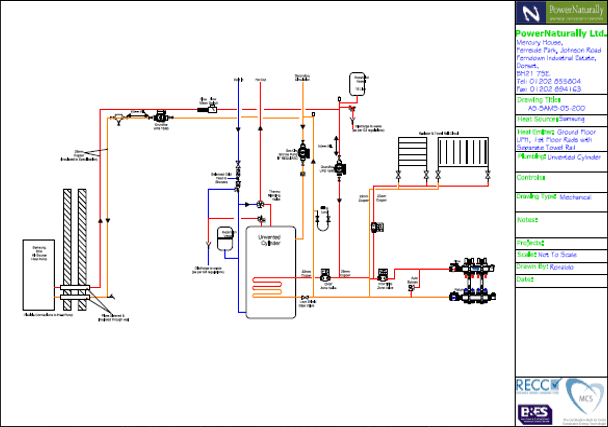

- Mechanical Schematics – project specific design setting out position of all system equipment both renewable and non renewable with all associated pipework and sizing

- Electrical Schematics – project specific design detailing all wiring connections for all equipment both renewables and non renewables including all heating controls

- Ground Loop Sizing – mcs approved calculation to determine pipe size and loop length based on energy demand and local ground geology

- Ground Loop Plan – site plan showing position of all ground loops and manifold location

- Compliance Certificate – compiled and issued based on all project design data and product performance figures for the purposes of obtaining MCS registration

- EPC Assessment – applications for RHI may require an upto date EPC which we can undertake if instructed

Installation

- ASHP – installation of the external unit, final pipework connections, and installation of internal hydrobox unit where applicable and all refrigerant lines

- GSHP – connection of ground loops to manifold, header pipe connection to heat pump and installation and final pipework connection of GSHP

- SOLAR PV – installation of roof hooks, mounting rails, PV panels, inverter, isolator switches and meter, and all wiring and connections

- SOLAR THERMAL – installation of roof hooks, mounting rails, solar thermal panels, pump station, expansion vessel and solar pipework and wiring connections

- MVHR – installation of ventilation ducting, air vents, air handling unit and all wiring connections

- UFH – installation of insulation, heat emitter plates, pipework and clipping, manifold, blending valves, wiring centre and thermostatic controls

Commissioning

- Flush & Test – in the case of ground loop installations to ensure no leaks are present and glycol levels are correct

- Set To Work – fire the system and test that it is fully operational

- Commission – check all settings and program the system to suit client requirements

- Warranties – register the installed product with the relevant manufacturers

- MCS Register – for NHBC sign off and possible RHI or FIT incentive applications requiring compliance certificates

- User Guides – provide easy to follow guides for operating the system

- System Demo – take the client through a hands on demonstration of how to operate the system

- Handover Pack – issue a full set of documentation including warranties, certificates and system details